Features

| MODEL | WRD 130 CNC | WRD 150 CNC | |

| COURSES | |||

| X – Column Longitudinal travel | mm | 5000-27000, in sections of 2000 | |

| Y – Headstock vertical travel | mm | 2000-5000, in sections of 500 | |

| Z – RAM stroke | mm | 1200 | |

| HEADSTOCK | |||

| Tool-holding slide diameter | mm | 450×450 | |

| Work spindle diameter | mm | 130 | 150 |

| W – Spindle stroke | mm | 700 | 800 |

| Main motor power S1/S6 | Kw | 37/46 | 51/65 |

| Work spindle speed range | 1/min | 10-3000 | 10-2500 |

| Torque on spindle S1/S6 | Nm | 2535/3152 | 2460/313 |

| FEEDS | |||

| X,Y,Z | mm/min | 24000 | |

| W | mm/min | 12000 | |

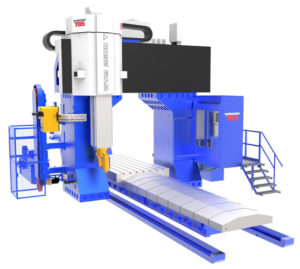

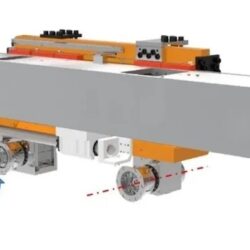

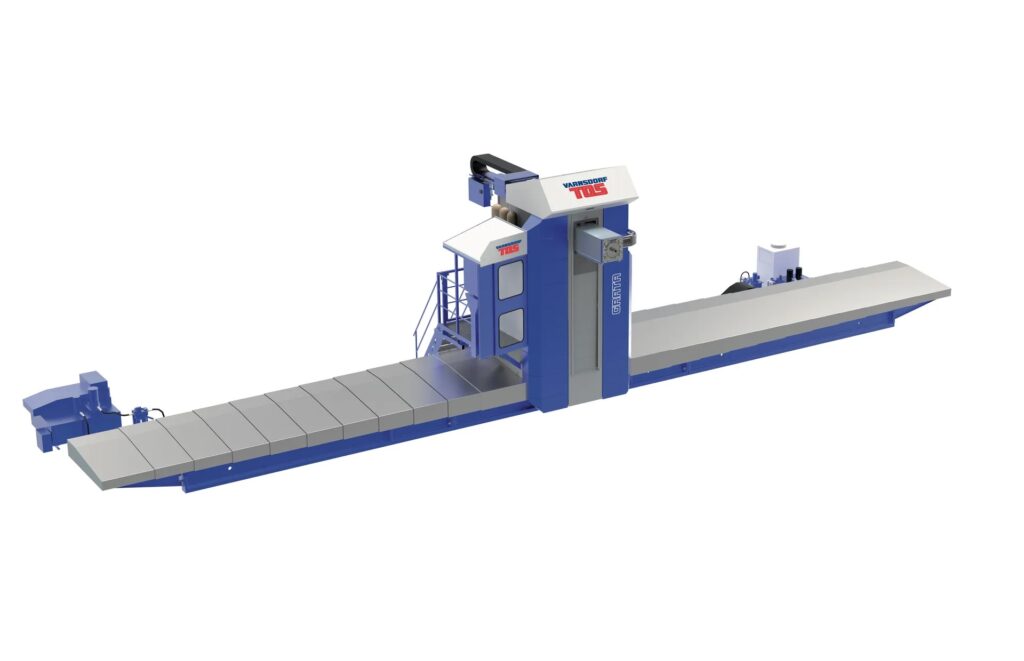

• The WRD 150 TOS Varnsdorf WRD boring milling machine has three kinds of boring bars with diameters of 130, 150 and 160 mm and high RPM even when using the same head and RAM. The table and the column are both cast, which makes the machine highly stable and dynamic. The carriage is guided using specially over-sized linear guides and has several tanks. The column feed is done using a rack and pinion and two motors with reducers driven by the CNC working in the master-slave system.

• The precision of the machining is guaranteed by the RAM fall compensation system that consists of a pivot in the frame that supports the RAM over the vertical sliding carriage it is supported on. The pivot is done using an offset and a reducer motor controlled by CNC and is continuously calibrated according to the rod and RAM output and the heads that may be installed.

• The machine can also be equipped with all kinds of automatic positioning heads with either millesimal positioning like the HUF or degree by degree positioning like the orthogonal HOI head.

• You can also install a face plate manufactured by TOS controlled by CNC through the movement of the rod like a D’Andrea face plate that acts like an extra axis.

• Rotating tables manufactured by TOS Varnsdorf of up to 80 tn and tilting tables can be installed.